Nov 6 - We got back from the cruise and 2 days later I was off working on a friends boat with another friend. You probably remember Bob's boat since I brought it down from Norfolk, VA to Ft. Myers. He and I had our boats stored at Glades Boat Storage where you can work on them yourselves. We asked our friend Bill - you also remember Bill - he went to the Bahamas with us. Bill had replaced a centerboard before so that was the number one item on the list. Bob had the centerboard in his garage and in it went when they moved his boat from storage to the position in the yard that you can work on boats.

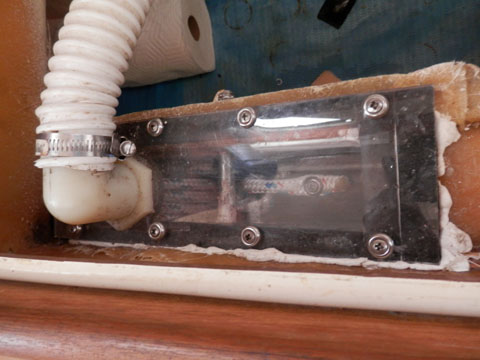

Bill came down the evening before and we had a great time together. Then we we went to breakfast with Bob on the way to Glades. We arrived, removed the bolt for the centerboard and found the bolt was corroded. Good thing I had ordered a new kit for the centerboard bolt from PCI. We were ready and when they lowered the boat towards the blocking, the board was in position and went into the slot perfectly. Once they had the boat blocked we went to work. We had one end of the up/down line attached to the board which was fished up into the slot. You can see the roller all wound up by Bill and ready to slip back into position. Bill fed the lines correctly and we put it all back together. Took up lots of slack then tied everything off and secured the end. All was good. By the way, you need 10 feet of 3/8 inch line to do this job! This fact isn't in any of the manuals!

To the lower right you can see the 5200 covering the bolt and washers. This should be waterproof! Not to mention a mess if it weren't for gloves.

This is a picture of us washing off the left over compound solution to ensure it was clean before the polymer wax was applied. I can't tell you how much better this looks in this picture because the process was very much worth the work!!!

We did this before sanding because I didn't want any of those products on the hull before we sanded then painted the hull.

The next morning it was sanding time. Yes, that is a bit of dirt on my face. Even thought I had a very good mask and goggles, the dirty mess hangs out. I had to wash that special hat from my friends up at the sail club in Muscle Shoals too.

It was a long time under the hull and Bob worked on cleaning up the outdrive and transom plate for us to repaint it.

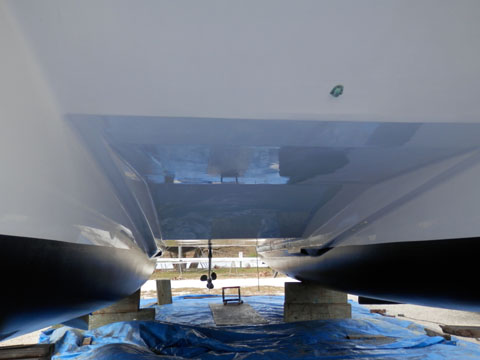

Bob finished up the outdrive and I painted the rest of the hull. After I was finished, I then polished the port side of the hull. It seems to be shining pretty darn good in this picture, doesn't it!

For those who don't know, the reason we painted the first coat blue was so he will know when he needs to do a bottom job again. When you see blue, you need to paint it again. We are putting two more coats of paint on and they will be black. On top of that, we will be putting another 4 or more coats on the leading edges of every part of the hull, centerboards and rudders. We will also be putting another layer of paint on the hull from the paint line down one full roller. This has provided me multi year service in the past and I expect it to do so again.

Speaking of black, there is the first coat. You can also see the transom plate for the outdrive has been primed and painted. I did the outdrive in my garage at home after we got the oil drain plug taken out by a machine shop.

We also got the starboard hull along with the front 1/4 underneath waxed before calling it a day.

This morning I took Deb and we voted. I showed pictures of the line on my Face book page. Deb is normally a late sleeper but this morning she was up at 6:15 and we were at the polls at 6:45 which is 15 minutes before they open. We were about 40-50 in line. By the time they opened there were another 50+ behind us. By now you've seen the lines in Florida and you can bet there is another controversy about the election down here. Unbelievable, but for those of us who actually stood our time and voted, we chose our side and we can at least talk about it. If you didn't vote..... well I'll simply relate something I learned a long time ago ....... There are people in the stands and there are people on the court. The only people that matter in any game are the people on the court. I hope everyone was on the court today.

I went back out and we mounted the the outdrive to the transom plate. Looking good, isn't it! Rotates well and everything feels wonderful. No leaks either.

Tomorrow, I'll be back out putting the third coat on the hull along with the rest of the coats, charging the battery, and polishing the rest of the underneath hull. I'll check out every system I can along with prelim checks on the engine of all fluids and ensure everything is ready for splash day.

Thursday morning we will put the newly made name signs on, registration numbers, wax the last few inches to the bottom paint and be ready to sand and paint the block points. We are going to keep the boat at their dock Thursday night to allow the paint to cure more before moving it on Friday back to Bob's dock.

More later. It's been a good project and the boat is standing tall again.

Nov 7 - Short update. Today, I painted the hulls for the third time and once it had flashed off, I painted the waterline down about a foot again. This gave us 4 coats all along the waterline and I had put at least 7 coats on all leading edges. After I waxed the underneath of the center of the hulls - next photo - I pulled off the tape giving us a clean line.

Looking good from the rub rail down. The top side is next week when we get it back to the dock.

Who waxes all of this? I do. Yep, all of it with a buffer. This had to be one of the hardest jobs I did waxing vertically with a random action buffer. You can see the results with the reflection in the hull. Looking good. Bob's boat is really looking good on the bottom side.

We clean up the 3 inches above the waterline in the morning and wax it too. We are also putting on his graphics for the boat name along with the registration numbers. Getting legal and ready for action.

I also checked out the engine fluids and reconnected the battery. I also topped off the outdrive with a bit more synthetic oil. Everything appears to be ready and we pick it up before lunch so we can do the blocking points and the rest of the centerboards. We splash at 1 pm and will leave it at the dock to ensure the bottom paint can cure where we touched up the block points. The boat will go back to the home dock on Friday. Bob can't wait and I'll be working on the inside on the trip home getting ready for the next projects. We are installing a windlass, fixing A/C, water system and whatever else we find not counting compounding the top, waxing and Woody Waxing the non-skid, fixing the drooping window foam, and polishing out the exterior windows. The boat should look almost like new and ready to go again.